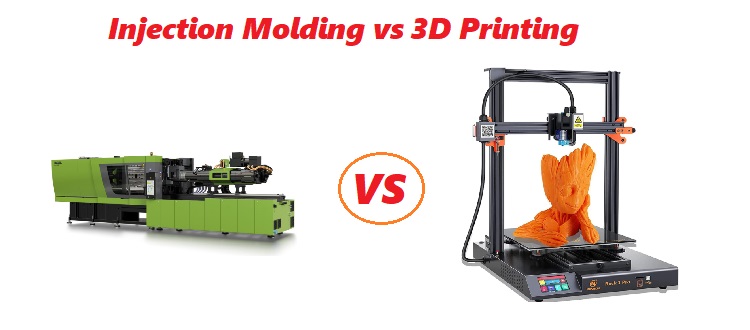

Both 3D printing and plastic injection molding are two ways to produce complex plastics parts. While originally considered competing technologies, both techniques have been acknowledged for their unique advantages that can be used in tandem with one another when looking at optimizing production efficiency.

Plastic Injection Molding

Injection molding is a fast production process that injects molten plastic into molds, where the material hardens and cools to become practical parts. Once these pieces are solidified, they can be removed from their confines for finishing touches. Every single mold lasts thousands of productions cycles before breaking down completely – it’s an investment in speed!

Pros of Plastic Injection Molding

Injection molding processes offer several benefits, including:

Low Unit Costs

When a prototype is created, it can be replicated by injecting melted plastic into an injection mold. Plastic injection molds are relatively cost-effective and don’t produce significant waste compared to other manufacturing processes. The simplest way of reusing these empty patterns again would be melting them down for reuse or recycling them in order to keep the production process sustainable.

Product Quality

The beauty of the injection molding process is that every millimeter in the mold is filled with detail and precision. In contrast, 3D printing only fills what it needs to in order for a design to be complete which can lead to unwanted bubbles or segmentation flaws on parts. The end result of an injection molded part will have smoother surfaces as well as functional integrity because there are no seams or assembly required before completion – making them more visually appealing and reliable than their counterparts made by other processes such as 3D printing.

Speed

Injection molding is a process that can be utilized quickly and efficiently to create products. It only takes seconds for the injection molded product to set, so many plastics don’t need any finishing touches before going out into the market place. The production time of an object will also depend on how large it is; most plates are able to hold more than one piece at once which multiplies their productivity rate by significant amounts in comparison with other methods like hand crafting or casting-in metal molds where each individual creation has its own unique design made specifically for them as they go down through different stages until completion.

Cons of Plastic Injection Molding

Injection molding has a few disadvantages, including:

Upfront Investment in the Mold

Creation of a mold is an expensive process. However, if the product has low demand and will only be used for one production cycle (or less), it may not make sense to invest in making a durable mold- unless that part can’t be easily reproduced with 3D printing technology.

You might think you’re saving money by investing into creating your own molds rather than using something like 3D printers or CNC machines but this isn’t always true! You’ll have to factor in how much material goes into each piece which could mean more spending on materials so keep that small cost analysis up during the design phase before finalizing anything too quickly without considering whether there’s another option out there.

Modification Limits

Molding a plastic part requires precision and time. To change the shape of your product after you’ve created the mold, it may be necessary to design an entirely new prototype!

Applications of Plastic Injection Molding

- High-volume production runs;

- Quality plastic products that require precision and consistency;

- Projects with long turnaround times;

- Any parts ranging from small and complex to large and simple.

Injection molding is a process that creates many identical objects at the same time. The one-step forming process makes it strong, and there’s no need to add an extra step to smooth out any rough edges because this can reduce friction between moving parts for applications like cars or other machines with lots of parts that are constantly in motion.

3D Printing Technology

3D printing is the latest in technology that has hit a mainstream audience. The process works by building up parts layer-by-layer with filament to create three dimensional objects from CAD files, one at a time.

Pros of 3D Printing

3D printing offers several benefits over plastic injection molding, such as:

Low Initial Cost

3D printing is a revolutionary way to make products. It doesn’t use specialized dies, meaning the printer can create one or hundreds of complete products at the same cost per unit!

Flexibility

3D printers allow for quick changes to an idea which makes it ideal as a prototyping tool. The ease of use and faster production time make this technology perfect when iterating through different design concepts or testing out stages in the product life cycle.

Cons of 3D Printing

3D printing can complicate the process in some cases:

Technical Issues

3D printing is a developing science which has led to many advances in health care and construction. However, there are potential risks associated with 3D printers that must be identified during the quality assurance process- while they may not seem substantial now, it’s important for us as humans looking ahead into our future to understand these risks before we commit ourselves further.

Speed

One of the drawbacks to 3D printing is that it may malfunction. The software and hardware sometimes fail, leading to errors in creating items which must be identified during quality assurance testing before they are used for production or sold as a finished product.

Product Quality

3D printing can create visible ridges and structural faults during manufacturing that typically don’t occur with plastic injection molding, but 3d printers are able to make great use of materials such as rubber and metal.

3D Printing is a more complex process than the traditional method for producing plastics; it also has benefits that other methods lack in terms of versatility when incorporating different types of material into an object.

Applications of 3D Printing

- Prototyping and testing products;

- Small production runs;

- Customized products;

- Products that are frequently modified or updated.

Limited-run objects are just one of the many things 3D printing can do. Prototypes and small batch production, among others, also fall under this category. Designs with a lot of gaps or holes in them will benefit from extra design support which is where 3D printing shines through as you need it to fill those spaces that may have been left without consideration for their size beforehand during your initial designs process. It’s easier to change things that are already there in a design. There is more room for errors because you can make changes before you start.

Injection Molding vs 3D Printing Difference

In injection molding, injection machines force molten liquid plastic to fill a cavity. The injection machine injects the melted material into a solid steel die that has been cooled by water or pressurized air. Because the filling is instantaneous and uniform, it will cool at an even rate so as not to distort or warp during cooling.

This type of manufacturing process also offers more control over product features than 3D printing because there are less variables in injection molding vs 3d printing such as temperature fluctuations caused by heating up both resin materials for example – which can cause distortions when they come out of the printer nozzle. Injection molding provides greater consistency between products with respect to their appearance, size and performance characteristics (such as strength). It is less expensive in injection molding costs than 3D printing because injection molds can be reused for many cycles.

In contrast to injection molding, 3D printers build products layer by layer from a digital file that is sliced into thin horizontal or vertical cross sections and then printed one at a time until the product is complete. The process of 3D printing is fundamentally different from injection molding because 3D printers require a computer-aided design (CAD) file for each product which can be time consuming and expensive to produce.

Moreover, the process of 3D printing itself is more difficult to control than injection molding – variable temperature fluctuations during print cycles will cause distortions when the layers come out of the printer nozzle. In other words, injection molding is more predictable and consistent than 3D printing – guaranteeing a better quality product each time.

3D Printing vs Injection Molding

Design is the key to 3D printing and injection molding. To start, we need a digital design with at least two things: structural integrity for our product’s durability during manufacturing process; and manufacturability so that it can be easily reproduced again in future production runs or by other companies.

What you need for 3D Printing

- Filament: this is plastic in its most raw, liquid form which comes spooled off of large coils like thread or yarn from a sewing kit. Check out our filament guide.

- Hot end: melts the filament and either extrudes it through small holes into layers or jets it against high pressure water, causing droplets to weld together while still maintaining their shape for injection molding purposes

- Cooling fan: moves air over the nozzle during printing so that things will cool quickly

- Build plate: the surface that supports the 3D printed object as it is being created. It can be heated or cooled to help maintain a particular consistency in the object.

- Computer: 3D printers are computers that have been specially programmed to precisely produce objects from a computer model .

- Software: 3D printers require software to function. There are many different types of 3D printer software, but it is typically recommended that a user use a software compatible with the 3D printer manufacturer.

- Computer monitor: this is used to display and manipulate 3D computer models that are fed into the 3D printer software

- Mouse: this is used to manipulate objects and change settings on the computer.

What do you need for injection molding?

- Injection press: this machine forces molten polymer through an injection nozzle

- Extrusion head: while there are different types, this part of the injection system moves hot material from one location to another within the injection press so that it can be forced out as if being squeezed past a small opening

- Mold: when you want 3D printed objects with complex shapes or textures, injection molding should be done using silicone molds which have been made specifically for each unique job by vacuum forming (a process where liquid plastic is pulled over thin sheets). These molds also allow for more precision in injection molding than 3D printing.

- Injection nozzle: this is a hot part of injection press that forces molten polymer material into the mold cavity

- Air knife: after injection, an air knife moves across top surface of object to remove excess material and prevent any contact with cooling mediums (such as water or oil) during cycle time

- Cooling unit: when rapidly produced items are being injection molded, it’s important to have a system for keeping these products cool before they can be removed from the molds. This helps maintain uniformity in color, shape, texture and size of each individual product. Whereas 3D printers usually use just fans or like objects need to stay cool on their own while still in the printer, injection molding systems are typically either water-cooled or oil-fed.

The injection molding process is more complicated to get started with than 3D printing because it requires a lot of specialized equipment and expertise in order for one injection unit to be successful at producing parts that meet industry standards for quality. Injection presses can cost anywhere from $200K – $500K and you need an engineer who has experience designing molds in CAD software (such as Solidworks)

While injection units do come equipped with certain features such as automated clamp loaders and air knives which make them capable of achieving high throughputs, they also require additional tools like special tool holders which are necessary for making consistent plastic products . This injection mold injection unit also needs to be capable of being programmed for the injection cycle time and various other variables related to injection, typically using PLCs.

When businesses to Use Injection Molding vs 3D Printing

When a customer needs hundreds of thousands, or even millions, of identical products in short time periods with low prices and quality assurance, manufacturers turn to injection molding. But it usually takes multiple iterations over weeks or months and many thousand dollars just to get the design exactly right. 3D printers can produce anything from water bottles for your next picnic outing (you don’t need an extra set) to automotive armrest panels; but that’s not always their best use case . For high volume mass production on tight deadlines at relatively small cost-per-part within large quantities – like million dollar Monopoly™ houses! – there is no better choice than tooled injection molding tools designed for longevity through durability after countless shots.

Although there are a few ways in which additive manufacturing can be used to make injection-molded parts better, I want to focus on three of them.

Rapid prototyping and testing

3D printers have the ability to quickly and cost-effectively print multiple prototype iterations until a final design is achieved before committing to an expensive mold. Further, most injection molds are also available as additive manufacturing filaments today; so if you’re interested in producing a certain type of IM product, it can be converted into filament beforehand through carefully selecting materials that work best for your needs. 3D printed test parts allow manufacturers exposure to different types of weather elements or post-process surface finishing which will then yield predictable results on their end for when they finally come time for production with plastic material injection molding!

Bridge to mass production

3D printing can help you get a head start on manufacturing and assembly during the time your mold is being produced. 3D printers are capable of producing end-use parts for initial production runs, allowing them to work as bridges from design approval to mass production! One example of this was COVID 19 PPE’s use of 3d printing in their process.

In the early stages of this pandemic, 3D printing was crucial for providing fast access to PPE. As soon as new designs were approved and traditional molds made, large numbers of injection-molded masks rolled off production lines that could not have come sooner enough. But while they waited on these tools rolling out onto store shelves in late 2018, fleets of 3D printers continued pumping out up high quality gear for first responders until then at a much more affordable cost than what you would find elsewhere!

Quality control and inspection

Injection molding parts are checked for size and shape to make sure they fall within spec before being moved to the assembly process. A Go/No-Go gauge is used verify that a part falls within established tolerances or if it doesn’t have any defects, while an assembly fixture ensures logos stay aligned with another piece of hardware or tool as well as many other applications. 3D printers can be helpful in quickly creating less expensive tools from lightweight polymers which helps save time without sacrificing quality.

3D printing techniques are not limited to just prototypes and models. They can also be used for the production of end-use parts, even if they’re only needed in a small number!

Final words

injection molding is less expensive to get started with than 3D printing and requires less space, but it has a higher upfront cost. injection units are able to produce more parts at one time, due in part to the automated features that come standard on injection presses. We recommend this process for large companies who have the capability of injection molding in-house.

injection presses are capable of handling injection cycles up to 3,000 parts per hour which is much faster than most 3D printers can achieve . This makes injection the preferred process for producing large quantities of objects quickly and affordably (for example molds that require a lot of small details).

Outcome: injection molding is a more complicated process that requires specialized equipment and knowledge, but it has the ability to produce an unlimited number of parts at once.

No Responses